Your Trusted Partner for

Wet Milling and Particle Reduction

Your Trusted Partner for Wet Milling and Particle Reduction

Find Media Mills and Lab Mixers for:

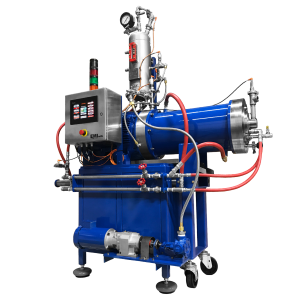

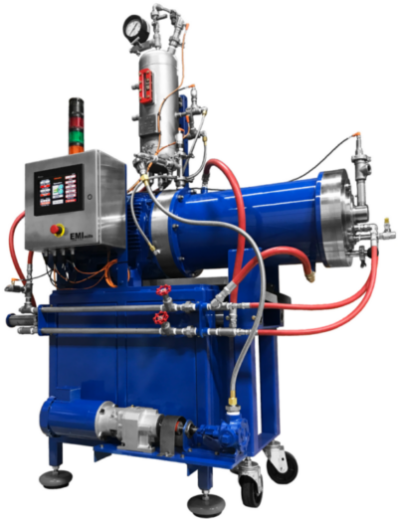

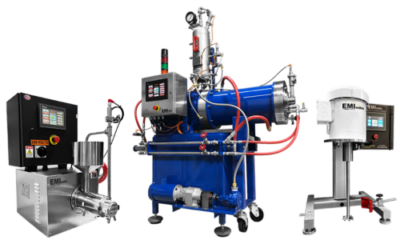

The Mini Mill

The Pilot Mill

The Production Mill

The Lab Mixer

The Lab Stirrer

Visit SCHOLD

Full-Service Support

Vice President of Sales

General Manager

Marketing and Sales

Operations Manager

Mechanical Engineer

President

Sales Engineer

Production

Production

Production

46

3,000+

2,000+

50+

Trusted Companies Using EMI Media Mills and Lab Mixers:

EMI Mills FAQs

Who is EMI Mills?

EMI Mills is a leading manufacturer of media mills (bead mills) and lab mixers for wet milling, fine grinding, and dispersing of liquids and pastes. We help industries achieve uniform and stable dispersions with narrow particle distributions, including nano-sized particles. Our equipment supports everything from research and development to full-scale commercial production.

What industries does EMI Mills serve?

Our equipment is used across a wide range of industries including:

-

Coatings, Paints, Inks

Achieving consistent color and smooth finishes

-

Pharmaceuticals

Precision particle reduction for active ingredients

-

Cosmetics

Uniform dispersions for smooth textures and enhanced product stability

-

Agrochemicals

Stable formulations for pesticides and fertilizers

-

Chemicals and Catalysts

Controlled milling for reaction efficiency

-

Food Colors, Dyes

Consistent color development for food and textiles

-

Fuel Cells, Battery Materials

Nano-level particle dispersion for performance

Since 1979, we have experience working with many other industries as well. Contact us to inquire about your specific application.

What happened to Eiger Machinery?

EMI Mills was founded in 1979 as Eiger Machinery, Inc. The company rebranded in 2011 as Engineered Mills, Inc. (EMI Mills) to better reflect its growing expertise in fine particle technology. In 2023, EMI Mills was acquired by SCHOLD, a leader in industrial mixing equipment. Over the years, we have built a reputation for high-quality milling solutions, premier customer support, and strong industry partnerships.

When did SCHOLD acquire EMI Mills, and what does it mean for customers?

SCHOLD acquired EMI Mills in 2023 to expand its milling, mixing, and dispersing equipment offerings. This partnership enhances the capabilities of both brands, allowing EMI to focus on advanced milling technologies while SCHOLD provides complementary industrial mixing and dispersing solutions. Customers now have access to a broader range of processing equipment, from pre-mixing with SCHOLD to fine particle milling with us.

How do EMI Mills and SCHOLD products work together?

EMI Mills specializes in media milling—reducing particle size through media mills (bead mills)—while SCHOLD offers industrial mixers and dispersers that optimize the pre-mix and let-down processes. Whether you are working with lab samples or production-scale batches, the combined product lineup provides a complete processing solution.

Is EMI Mills equipment made in the USA?

Yes! Our facility is located in Grayslake, IL and all equipment and parts are engineered and manufactured here. Our parent company SCHOLD is located in Chicago, IL. At EMI Mills, product quality and customer support is priority #1.

Do you have used / in-stock equipment?

Yes! We have an inventory of in-stock media mills, lab mixers, and SCHOLD industrial mixers for purchase or short-term rental. This is a great option when the budget is tight and/or equipment is needed ASAP.

Media Milling and Lab Mixing FAQs

What is media milling, and how does it work?

Media milling, or bead milling, uses high-energy grinding media (beads) to break down particles into fine or nano-scale dispersions. The media creates shear and impact forces that reduce agglomerates and ensure uniform particle size distribution.

How do I choose the right EMI Mill for my application?

The right media mill depends on batch size, desired particle size, product viscosity, and material sensitivity. We offer:

- The Mini Mill for lab-scale R&D

- The Pilot Mill for process development and small production runs

- The Production Mill for high-volume continuous processing

Our parent company SCHOLD provides additional milling options including the Vertical Media Mill and Immersion Mill.

How do I choose the right grinding media for my mill?

Selecting the right grinding media depends on factors like product viscosity, particle size requirements, and material hardness. EMI Mills offers glass, zirconium silica, cerium-stabilized zirconia, yttrium-stabilized zirconia, YTZ, and steel to match various applications.

How do I prevent contamination during media milling?

Using high-purity ceramic grinding media (e.g., YTZ or yttrium-stabilized zirconia) minimizes contamination, especially for applications like pharmaceuticals or electronics. Proper mill cleaning and maintenance also help maintain product purity.

Can media milling achieve nano-particle sizes?

Yes, with the right combination of mill design, media selection, and processing parameters, media mills can produce sub-micron and even nano-scale dispersions.

What is the difference between lab mixers and production mixers?

Lab mixers are designed for small-batch testing, formulation development, and process optimization, while production mixers handle large-scale manufacturing. We offer lab mixers, our parent company SCHOLD provides production mixers and dispersers.

What factors should I consider when choosing a lab mixer?

Key considerations include batch size, viscosity, shear requirements, and the type of mixing action needed (high-speed dispersion, low-shear blending, or milling). Contact us to discuss your application.

How does pre-mixing affect milling efficiency?

Proper pre-mixing ensures a uniform dispersion before milling, reducing processing time and improving particle size consistency. Our lab mixers and SCHOLD industrial mixers provide effective pre-mixing solutions.