CHILLERS

(Lab or Production)

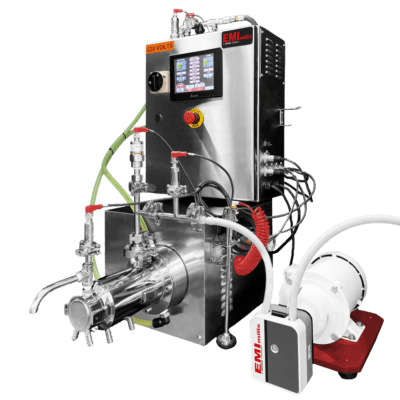

EMI Mills chillers provide a clean, reliable alternative to tap water cooling, ensuring temperature-controlled fluid for closed-loop cooling in both laboratory and production environments. Unlike tap water, our chillers prevent scale buildup, eliminate temperature fluctuations, and deliver powerful, precise cooling for your processing needs.

- Reliable Performance – Maintain constant cooling with no fluctuations.

- Consistent Pumping Power – Ensures steady flow rates for optimal heat dissipation.

- No Scale Buildup – Prevents contamination and maintenance issues.

- Precise Temperature Control – Set and maintain exact temperatures for repeatable results.

Available in various sizes, our chillers are designed to meet the unique cooling demands of your application. Contact us to take the guesswork out of selecting the right chiller for your process.

Description

Chiller FAQs

How do I choose the right chiller for my application?

The right chiller depends on factors such as cooling capacity, temperature range, and required flow rate. We have extensive experience in selecting chillers specifically for dispersion and milling applications, so don’t hesitate to contact us.

What are the benefits of using a chiller over tap water cooling?

Unlike tap water, a chiller provides consistent cooling without fluctuations, eliminates scale buildup, and reduces water waste, making it a more reliable and cost-effective solution.

Are EMI Mills chillers compatible with all milling and mixing equipment?

Yes! We offer chillers that integrate seamlessly with our media mills and lab mixers, ensuring efficient cooling and temperature stability during processing.

Do EMI Mills chillers require regular maintenance?

Routine maintenance, such as checking fluid levels and cleaning filters, helps maintain performance and longevity. Contact us for recommendations on best practices for upkeep.

Chiller FAQs

How do I choose the right chiller for my application?

The right chiller depends on factors such as cooling capacity, temperature range, and required flow rate. We have extensive experience in selecting chillers specifically for dispersion and milling applications, so don’t hesitate to contact us.

What are the benefits of using a chiller over tap water cooling?

Unlike tap water, a chiller provides consistent cooling without fluctuations, eliminates scale buildup, and reduces water waste, making it a more reliable and cost-effective solution.

Are EMI Mills chillers compatible with all milling and mixing equipment?

Yes! We offer chillers that integrate seamlessly with our media mills and lab mixers, ensuring efficient cooling and temperature stability during processing.

Do EMI Mills chillers require regular maintenance?

Routine maintenance, such as checking fluid levels and cleaning filters, helps maintain performance and longevity. Contact us for recommendations on best practices for upkeep.