GRINDING MEDIA

(New or Replacement)

We offer a wide range of grinding media to enhance milling efficiency, extend equipment life, and achieve precise particle size reduction. Selecting the right media type, size, and density is critical for optimizing performance. Utilize technical support to determine the ideal grinding media for your process. Available options:

- Glass (2.5 sg) – 0.3–3.0 mm | Cost-effective for low-viscosity dispersions

- Zirconium Silica (3.8 sg) – 0.8–3.0 mm | Versatile for general milling applications

- Cerium Stabilized Zirconia (6.2 sg) – 0.3–2.5 mm | High-performance with excellent wear resistance

- Yttrium Stabilized Zirconia (6.0 sg) – 0.3–2.5 mm | Durable and efficient for fine particle reduction

- YTZ (6.0 sg) – 0.3–2.5 mm | High-density media for demanding applications

- Steel (7.2 sg) – 0.8–3.0 mm | Heavy-duty impact milling for tough materials

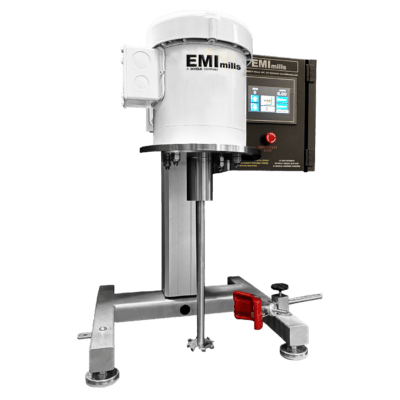

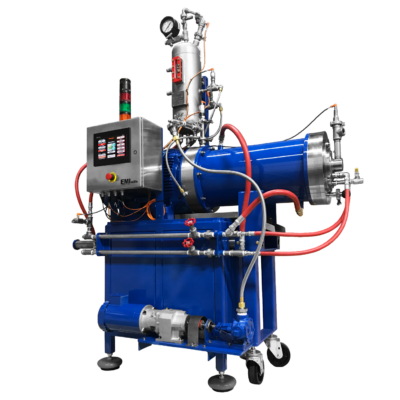

Need a new mill? Explore media mills page. Pre-mix equipment to round out your process? Get started with SCHOLD industrial mixers.

Description

Selecting the Right Grinding Media

Choosing the correct grinding media is essential for achieving the best milling results. Key factors to consider when selecting grinding media include:

-

Particle Size & Distribution

Smaller beads create finer dispersions, while larger beads provide higher impact for rapid size reduction.

-

Viscosity & Flow Properties

Low-viscosity liquids can accommodate smaller media, whereas high-viscosity pastes require larger, denser beads.

-

Impact vs. Shear Forces

Larger beads deliver more impact energy, while smaller beads increase surface area for finer grinding.

-

Material Compatibility

Non-reactive media prevent contamination and ensure product purity in sensitive applications.

Benefits of Quality Grinding Media

Investing in high-quality grinding media enhances milling efficiency, improves product consistency, and reduces operational costs. Benefits include:

-

Extended Media Life

Advanced ceramic compositions offer increased hardness and wear resistance.

-

Lower Equipment Wear

Smooth surfaces and uniform bead sizes minimize mill component degradation.

-

Consistent Milling Performance

Optimized bead density and size lead to predictable particle size distribution.

-

Reduced Processing Time

High-performance media allow for faster particle reduction and dispersion.

Grinding Media FAQs

What is the benefit of using higher-density grinding media?

Higher-density media provide more energy during milling, improving dispersion and reducing processing time. They also offer better wear resistance, extending both media and equipment life.

Can different grinding media be mixed in the same mill?

Mixing media types or sizes is generally not recommended, as it can lead to uneven milling and inconsistent results. It’s best to use a uniform bead size and material to maintain efficiency and process control.

How do I know when to replace my grinding media?

Signs that media need replacement include reduced milling efficiency, increased process times, and visible wear or breakage. Regular inspections and maintaining proper bead loading can help extend media life.

Does grinding media affect contamination levels?

Yes, the composition of the media plays a role in contamination. High-purity ceramic beads minimize contamination, making them ideal for sensitive applications, while steel beads may introduce trace elements into the product.

What maintenance is required for grinding media?

Proper storage, regular cleaning, and avoiding exposure to extreme conditions help prolong media life. Flushing the mill between product runs can also prevent buildup and contamination.

Where can I get assistance with grinding media selection?

We provide expert guidance to help you choose the best grinding media for your process. Contact our team for recommendations tailored to your application.