The LAB MIXER

Bench-Top Disperser

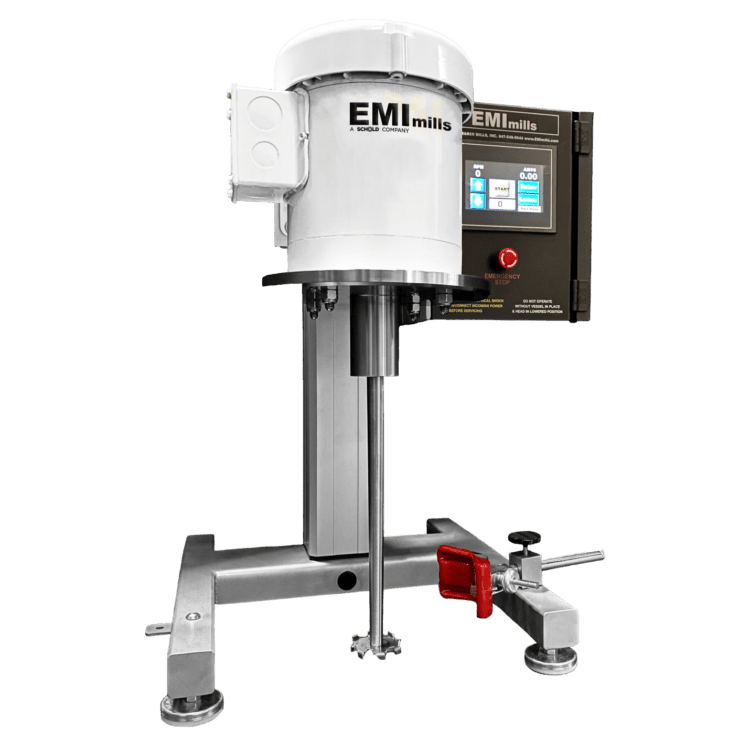

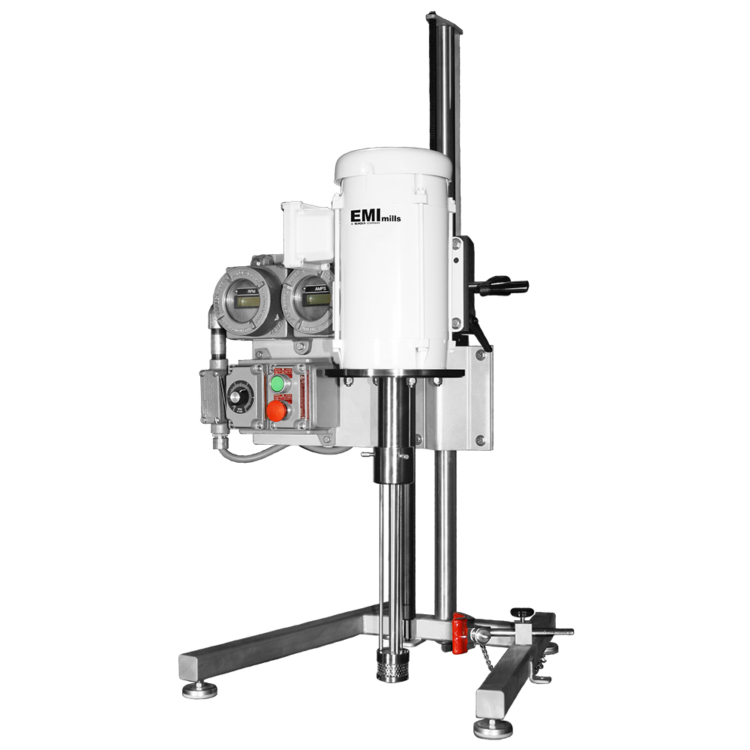

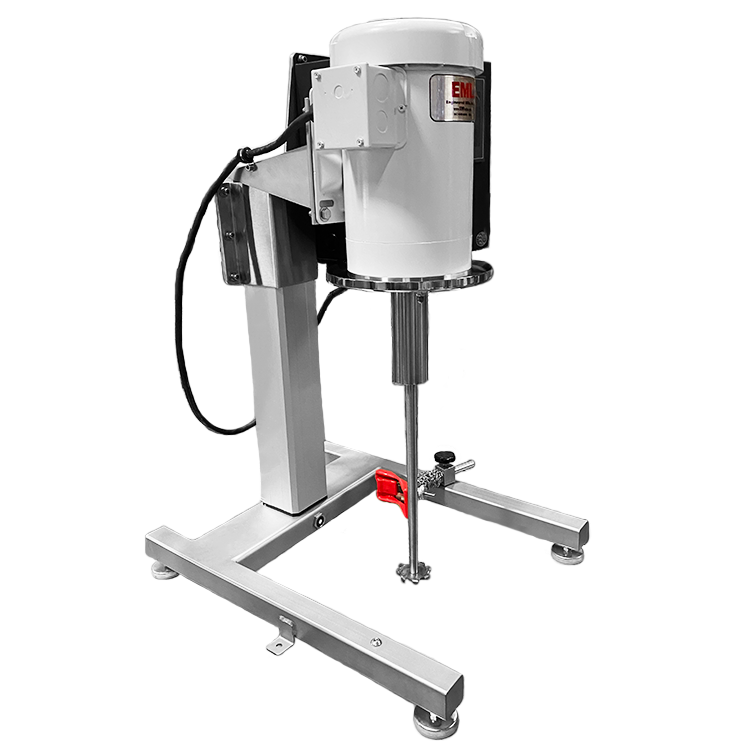

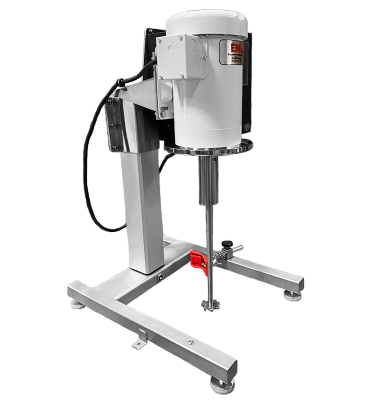

The Lab Mixer is a versatile bench-top disperser for laboratory and pilot-scale processing. Ideal for producing batches up to 10 gallons (~40 L), this compact yet powerful unit delivers precise control over your mixing and dispersion process. Whether you need high-shear dispersion for fine particle reduction or low-speed mixing for uniform blending, the Lab Mixer adapts with multiple blade configurations and advanced controls.

- Variable-speed motor for consistent performance

- Multiple blade configurations for dispersing or mixing

- Interchangeable blades to customize batch-to-batch

- Digital gauges and PLC controls (optional) for process monitoring

- Head lift systems and shaft guards for safe operation

- Stainless steel contact components for sanitary requirements

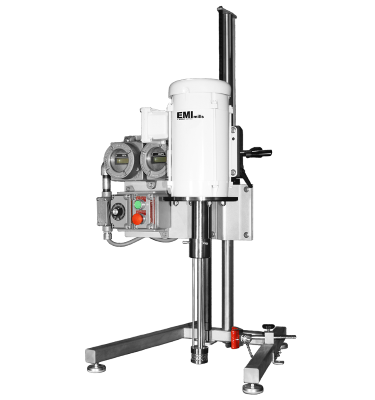

- Explosion-proof (XP) options available for hazardous environments

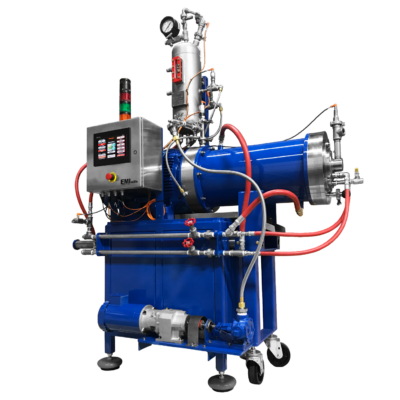

Need more particle reduction? Find the lab and pilot media mills. Mixing or dispersing larger batches? Explore SCHOLD industrial mixers and dispersers.

Description

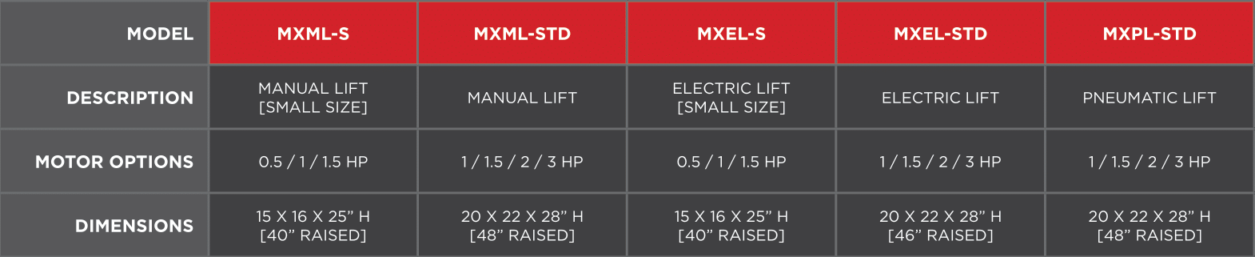

Lab Mixer Specifications

Note: All models include a variable frequency drive (VFD) for speed control and various power voltage options are available.

MXML-S (Manual Lift, Small)

- Motor Options: 0.5 / 1 / 1.5 HP

- Dimensions: 15 x 16 x 25” H (40” Raised)

MXML-STD (Manual Lift)

- Motor Options: 1 / 1.5 / 2 / 3 HP

- Dimensions: 20 x 22 x 28” H (48” Raised)

MXEL-S (Electric Lift, Small)

- Motor Options: 0.5 / 1 / 1.5 HP

- Dimensions: 15 x 16 x 25” H (40” Raised)

MXEL-STD (Electric Lift)

- Motor Options: 1 / 1.5 / 2 / 3 HP

- Dimensions: 20 x 22 x 28” H (46” Raised)

MXPL-STD (Pneumatic Lift)

- Motor Options: 1 / 1.5 / 2 / 3 HP

- Dimensions: 20 x 22 x 28” H (48” Raised)

Lab Mixer Features

Multiple Configurations

Choose from manual, electric, or pneumatic lift models to suit your lab setup and processing needs. Whether you require a compact solution or enhanced automation, we have an option that fits.

Custom Blade Options

- High-Shear Blades – Ideal for breaking down solids and achieving fine dispersions.

- Axial Flow Blades – Designed for efficient liquid movement and circulation in lower-viscosity applications.

- Bowtie Blades – Provide effective low-shear blending for delicate formulations.

- Rotor Stator – Enhances mixing intensity by combining mechanical impact forces with hydraulic shearing for dispersing, emulsifying, and homogenizing.

Variable Speed Control

Dial in the precise mixing or dispersion intensity required for your application. Adjustable speeds allow for gentle agitation or high-shear dispersion, providing flexibility for different material viscosities.

Heavy-Duty Motor

Built with durable, high-quality motors ranging from 0.5 HP to 3 HP, the Lab Mixer delivers reliable and repeatable results batch after batch, reducing downtime and increasing productivity.

Stainless Steel Contact Parts

All wetted components are constructed from stainless steel, ensuring durability, corrosion resistance, and compliance with sanitary or cleanroom environments.

Advanced Control Options

Select from general-purpose controls, explosion-proof (XP) options for hazardous environments, or PLC systems with digital monitoring. PLC models offer enhanced functionality such as real-time power, temperature, and RPM tracking for better process control.

Safety Enhancements

Engineered for operator protection, our mixers include adjustable vessel clamps, safety switches to prevent operation when the head is raised, and optional shaft guards for additional security.

Lab Mixing and EMI Lab Mixer FAQs

What is the difference between mixing and dispersing?

Mixing refers to the process of combining multiple components into a uniform blend, often with low shear. Dispersing, on the other hand, involves breaking down agglomerates and evenly distributing fine particles throughout a liquid medium, typically using high shear forces.

How do I choose the right lab mixer for my application?

The right lab mixer depends on factors such as batch size, material viscosity, and desired particle size reduction. If you need high-shear dispersion for breaking down solids or creating stable emulsions, a disperser with variable speed control and custom blade options is ideal.

Why is variable speed important in lab mixing?

Variable speed control allows you to fine-tune shear intensity based on your material’s properties, preventing over-processing or under-dispersing. This ensures batch-to-batch consistency and better product stability.

Can lab mixers be used for scale-up to production?

Yes. Lab mixers are commonly used for research and development before scaling up to larger production equipment. Our mixers provide a seamless transition to pilot or full-scale production (i.e. SCHOLD industrial mixers).

What blade options are available for the EMI Lab Mixer?

- High-Shear Blades – Ideal for breaking down solids and achieving fine dispersions.

- Axial Flow Blades – Designed for efficient liquid movement and circulation in lower-viscosity applications.

- Bowtie Blades – Provide effective low-shear blending for delicate formulations.

- Rotor Stator – Enhances mixing intensity by combining mechanical impact forces with hydraulic shearing for dispersing, emulsifying, and homogenizing.

What if I need to produce larger batch sizes?

No problem. Our parent company, SCHOLD has a range of industrial-sized dispersers/mixers to handle any-sized batch.

Does the EMI Lab Mixer come with safety features?

Yes. Safety is a priority, and our mixers include vessel clamps, shaft guards, and safety interlocks that prevent operation when the head is raised, ensuring a secure mixing process.

Can the EMI Lab Mixer be integrated with other EMI Mills equipment?

Absolutely. Our lab mixers are designed to work seamlessly with our media mills and other processing equipment, allowing for a complete and efficient milling and dispersion process.

What industries commonly use the EMI Lab Mixer?

Our Lab Mixers are used across a variety of industries, including coatings, inks, cosmetics, pharmaceuticals, chemicals, specialty materials, and more. Contact us to inquire about your application.

How do I maintain and clean my EMI Lab Mixer?

Stainless steel wetted parts make cleaning easy, and routine checks on motor performance, blade wear, and control settings maintain consistent results. We also offer replacement parts and technical support.

Lab Mixing and EMI Lab Mixer FAQs

What is the difference between mixing and dispersing?

Mixing refers to the process of combining multiple components into a uniform blend, often with low shear. Dispersing, on the other hand, involves breaking down agglomerates and evenly distributing fine particles throughout a liquid medium, typically using high shear forces.

How do I choose the right lab mixer for my application?

The right lab mixer depends on factors such as batch size, material viscosity, and desired particle size reduction. If you need high-shear dispersion for breaking down solids or creating stable emulsions, a disperser with variable speed control and custom blade options is ideal.

Why is variable speed important in lab mixing?

Variable speed control allows you to fine-tune shear intensity based on your material’s properties, preventing over-processing or under-dispersing. This ensures batch-to-batch consistency and better product stability.

Can lab mixers be used for scale-up to production?

Yes. Lab mixers are commonly used for research and development before scaling up to larger production equipment. Our mixers provide process consistency, allowing for a seamless transition to pilot or full-scale production.

What blade options are available for the EMI Lab Mixer?

- High-Shear Blades – Ideal for breaking down solids and achieving fine dispersions.

- Axial Flow Blades – Designed for efficient liquid movement and circulation in lower-viscosity applications.

- Bowtie Blades – Provide effective low-shear blending for delicate formulations.

- Rotor Stator – Enhances mixing intensity by combining mechanical impact forces with hydraulic shearing for dispersing, emulsifying, and homogenizing.

What if I need to produce larger batch sizes?

No problem. Our parent company, SCHOLD has a range of industrial-sized dispersers/mixers to handle any-sized batch.

Does the EMI Lab Mixer come with safety features?

Yes. Safety is a priority, and our mixers include vessel clamps, shaft guards, and safety interlocks that prevent operation when the head is raised, ensuring a secure mixing process.

Can the EMI Lab Mixer be integrated with other EMI Mills equipment?

Absolutely. Our lab mixers are designed to work seamlessly with our media mills and other processing equipment, allowing for a complete and efficient milling and dispersion process.

What industries commonly use the EMI Lab Mixer?

Our Lab Mixers are used across a variety of industries, including coatings, inks, cosmetics, pharmaceuticals, chemicals, specialty materials, and more. Contact us to inquire about your application.

How do I maintain and clean my EMI Lab Mixer?

Stainless steel wetted parts make cleaning easy, and routine checks on motor performance, blade wear, and control settings maintain consistent results. We also offer replacement parts and technical support.