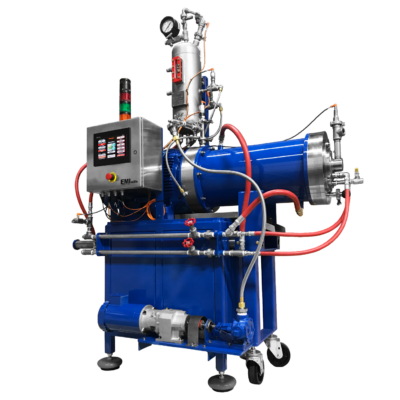

The MINI MILL

Lab Media Mill

The Mini Mill is a self-contained horizontal media mill for laboratory and small-scale milling, fine grinding, and dispersing liquid applications. It is ideal for product research, quality control, technical service applications, and scaling to production batches. This lab media mill utilizes grinding media to develop the high shear and impact forces required to reduce agglomerates or finite particles.

Sample Size Range: 25 mL – 10 L

- Capable of producing sub-micron particles

- Includes built-in pump and pre-disperser as required

- Single pass or re-circulation milling

- General purpose, explosion proof, or intrinsically safe electrical controls

- PLC diagnostic controls available for operating, monitoring, and data collection

- Quick release latches allow easy removal of components

- Customizable to meet requirements

Want recirculation? The Pilot Mill design makes it simple. Milling larger batches? The robust Production Mill is optimal for scaling production. Explore other milling options by SCHOLD, including the Vertical Media Mill or post-mounted Immersion Mill.

Description

Mini Mill Specifications

Note: Larger feed funnels are available to increase sample size and agitator tip speeds range from 0-16 m/s for all models.

M25

- Chamber Volume: 25 mL

- Sample Size: 25 – 100 mL

- Power: 1HP

- Agitator Speed: 0 – 5000 RPM

M50

- Chamber Volume: 50 mL

- Sample Size: 50 – 250 mL

- Power: 1HP

- Agitator Speed: 0 – 5000 RPM

M100

- Chamber Volume: 100 mL

- Sample Size: 100 – 500 mL

- Power: 2HP

- Agitator Speed: 0 – 5000 RPM

M250

- Chamber Volume: 250 mL

- Sample Size: 250 – 4000 mL

- Power: 3HP

- Agitator Speed: 0 – 5000 RPM

M750

- Chamber Volume: 750 mL

- Sample Size: 1000 – 4000 mL

- Power: 5HP

- Agitator Speed: 0 – 3500 RPM

M1000

- Chamber Volume: 1000 mL

- Sample Size: 1200 – 4000 mL

- Power: 5HP

- Agitator Speed: 0 – 3500 RPM

M2000

- Chamber Volume: 2000 mL

- Sample Size: 2200 – 7000 mL

- Power: 7.5HP

- Agitator Speed: 0 – 3500 RPM

Mini Mill Features

Re-Circulation and Single Pass Modes

With the Mini Mill’s end plate set to re-circulate, RPM is increased to desired level and product recirculates until quality is achieved. After re-circulation and setting end plate to single pass, throughput can be adjusted from minimum to maximum flow rates.

Self-Contained or External Pump

The Mini Mill’s built-in, two-state internal pumping mechanism ensures controllable pumping rates, important particularly for high-viscosity applications. A separate pump is available if required.

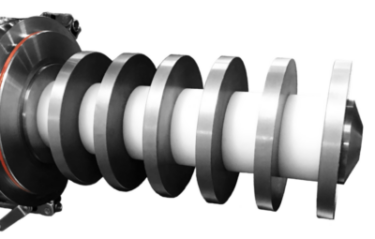

Bead Separation Options

0.06 – 1.0 mm screen separators available for bead sizes 0.1 – 2.5 mm. Special arrangements can be made for smaller media sizes.

Temperature Control

The Mini Mill is designed with a water-jacketed chamber and optional additional end plate cooling for precise temperature regulation. Chillers are available if needed.

Simple Cleaning

Addition of suitable solvent to the feed funnel with end plate in re-circulation position allows for efficient cleaning. Mini Mill components can be quickly dismantled when necessary.

Custom Controls

General purpose, explosion-proof, and intrinsically safe options are available. PLC controls include a color display, programming for operation, monitoring process variables, data collection, and more.

Lab Milling and Mini Mill FAQs

What is a lab mill?

A lab mill is a small-scale milling device used for research, development, and testing of materials. It produces small batches and fine-tunes formulations before scaling up to production, making it essential for laboratories working on product development, quality control, and technical services.

What is lab milling?

Lab milling refers to the process of grinding, dispersing, and mixing materials in a controlled, small-scale environment. It enables precise adjustments to product formulations and milling conditions, ensuring that the process can be replicated during large-scale production.

Why is pre-mixing important for efficient milling?

Pre-mixing ensures uniform distribution of the material before milling, improving the overall efficiency of the process. It breaks down larger particles and agglomerates, reducing the workload of the mill and shortening processing times for better final product. Our lab mixers are a great place to start.

What is the difference between single-pass and recirculation milling?

Single-pass milling processes the material through the mill once, while recirculation milling sends the material through the mill multiple times. Recirculation is ideal for achieving finer particle sizes and more thorough dispersion, as the material has more time in contact with the grinding media.

What types of materials can be processed in the Mini Mill?

The Mini Mill is suitable for a wide range of liquid applications, including coatings, inks, pharmaceuticals, cosmetics, specialty chemicals, and more. It handles both low and high-viscosity materials, providing flexibility for various laboratory needs.

What sample size range can the Mini Mill handle?

The Mini Mill processes sample sizes ranging from 25 mL to 10 L, depending on the model, providing options for both small-scale testing and slightly larger production batches.

Can the Mini Mill be customized for my application?

Yes, the Mini Mill is highly customizable, with options for different chamber sizes, bead separation, pumping mechanisms, and control systems. Contact our team to determine the best configuration for your specific process.

What grinding media can be used in the Mini Mill?

The Mini Mill is compatible with a wide range of grinding media, including ceramic, glass, steel, and others. Media sizes range from 0.1 mm to 2.5 mm, with the option for custom bead sizes to suit your application.

What are the modes of operation for the Mini Mill?

The Mini Mill operates in both single-pass and recirculation modes. In recirculation mode, the material is repeatedly passed through the mill to achieve finer results, while in single-pass mode, throughput can be adjusted to meet specific flow rate requirements.

How does the Mini Mill handle temperature control?

The Mini Mill comes with a water-jacketed chamber and optional additional cooling for the end plate to maintain precise temperature regulation. This ensures stable processing conditions and preventing overheating. Chillers are also available if needed.

How easy is it to clean the Mini Mill?

Cleaning the Mini Mill is simple, with quick-release components and the ability to use solvents during re-circulation for efficient cleaning. This makes it easy to switch between different formulations with minimal downtime.

What kind of controls are available for the Mini Mill?

The Mini Mill offers general-purpose, explosion-proof, and intrinsically safe control options. PLC diagnostic controls are available for operating, monitoring, and data collection, providing full control over process variables and allowing for easy troubleshooting.

Lab Milling and Mini Mill FAQs

What is a lab mill?

A lab mill is a small-scale milling device used for research, development, and testing of materials. It produces small batches and fine-tunes formulations before scaling up to production, making it essential for laboratories working on product development, quality control, and technical services.

What is lab milling?

Lab milling refers to the process of grinding, dispersing, and mixing materials in a controlled, small-scale environment. It enables precise adjustments to product formulations and milling conditions, ensuring that the process can be replicated during large-scale production.

Why is pre-mixing important for efficient milling?

Pre-mixing ensures uniform distribution of the material before milling, improving the overall efficiency of the process. It breaks down larger particles and agglomerates, reducing the workload of the mill and shortening processing times for better final product. Our lab mixers are a great place to start.

What is the difference between single-pass and recirculation milling?

Single-pass milling processes the material through the mill once, while recirculation milling sends the material through the mill multiple times. Recirculation is ideal for achieving finer particle sizes and more thorough dispersion, as the material has more time in contact with the grinding media.

What types of materials can be processed in the Mini Mill?

The Mini Mill is suitable for a wide range of liquid applications, including coatings, inks, pharmaceuticals, cosmetics, specialty chemicals, and more. It handles both low and high-viscosity materials, providing flexibility for various laboratory needs.

What sample size range can the Mini Mill handle?

The Mini Mill processes sample sizes ranging from 25 mL to 10 L, depending on the model, providing options for both small-scale testing and slightly larger production batches.

Can the Mini Mill be customized for my application?

Yes, the Mini Mill is highly customizable, with options for different chamber sizes, bead separation, pumping mechanisms, and control systems. Contact our team to determine the best configuration for your specific process.

What grinding media can be used in the Mini Mill?

The Mini Mill is compatible with a wide range of grinding media, including ceramic, glass, steel, and others. Media sizes range from 0.1 mm to 2.5 mm, with the option for custom bead sizes to suit your application.

What are the modes of operation for the Mini Mill?

The Mini Mill operates in both single-pass and recirculation modes. In recirculation mode, the material is repeatedly passed through the mill to achieve finer results, while in single-pass mode, throughput can be adjusted to meet specific flow rate requirements.

How does the Mini Mill handle temperature control?

The Mini Mill comes with a water-jacketed chamber and optional additional cooling for the end plate to maintain precise temperature regulation. This ensures stable processing conditions and preventing overheating. Chillers are also available if needed.

How easy is it to clean the Mini Mill?

Cleaning the Mini Mill is simple, with quick-release components and the ability to use solvents during re-circulation for efficient cleaning. This makes it easy to switch between different formulations with minimal downtime.

What kind of controls are available for the Mini Mill?

The Mini Mill offers general-purpose, explosion-proof, and intrinsically safe control options. PLC diagnostic controls are available for operating, monitoring, and data collection, providing full control over process variables and allowing for easy troubleshooting.