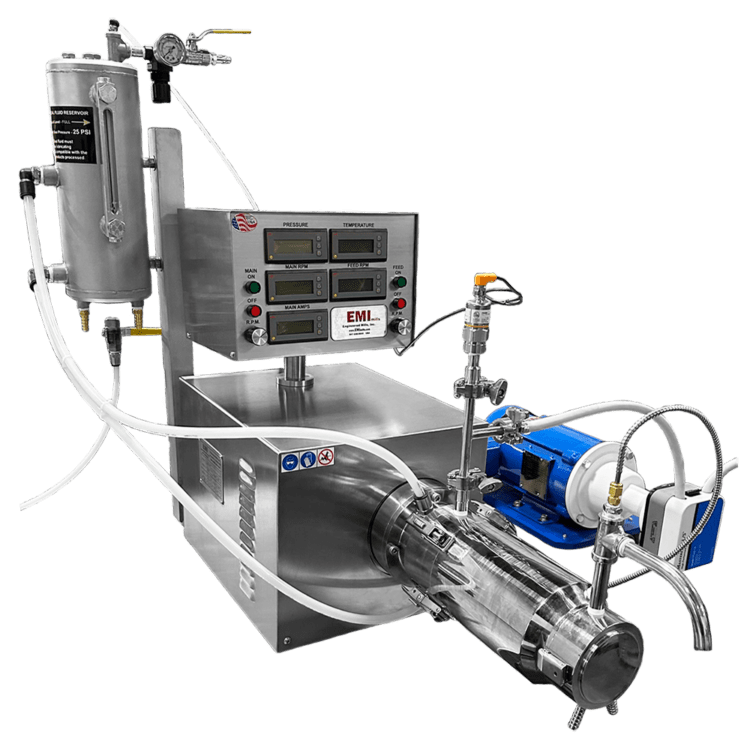

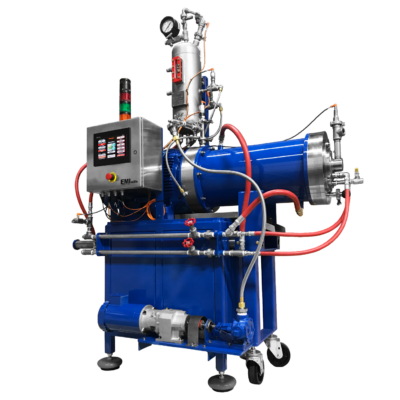

The PILOT MILL

Lab Media Mill

The Pilot Mill is a lab media mill designed for wet milling, fine grinding, and dispersing fluid or paste applications. It is ideal for product research, quality control, and scaling to production batches. This lab mill provides precise control over key variables like product flow and agitator speed, allowing users to replicate full-scale production conditions.

Sample Size Range: 1 – 100+ L

- Sub-micron particle size – Achieve ultra-fine grinding for precise formulations.

- Continuous or recirculation milling – Optimize process control for consistent results.

- Flexible processing modes – Supports single-pass, multiple-pass, or batch operation.

- Variable-speed agitator – Fine-tune dispersion with precise speed control.

- Durable construction – Available in various materials for compatibility.

- PLC controls – Monitor key process variables for consistency.

- Quick-release closures – Simplify cleaning and maintenance.

Ready for larger batches? The robust Production Mill is optimal for scaling production. Explore other milling options by SCHOLD, including the Vertical Media Mill or post-mounted Immersion Mill.

Description

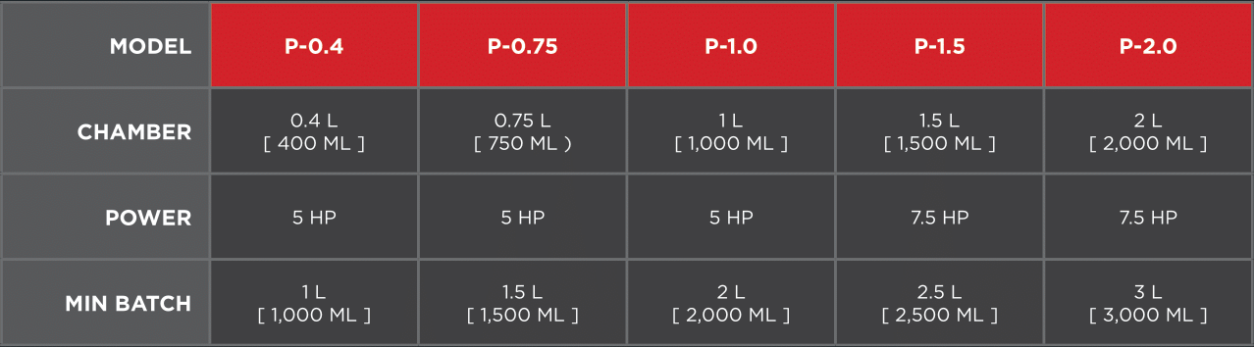

Pilot Mill Specifications

The Pilot Mill is available in multiple chamber sizes to meet your process requirements. Contact us to determine the best lab media mill configuration for your application. See below to get started.

Notes: Larger feed funnels are available to increase sample size and agitator tip speeds range from 0-16 m/s for all models. All Pilot Mills include mechanical seals and safety switches for operation.

P-0.4

- Chamber Volume: 0.4 L (400 mL)

- Power: 5 HP

- Min Batch Volume: 1 L

P-0.75

- Chamber Volume: 0.75 L (750 mL)

- Power: 5 HP

- Min Batch Volume: 1.5 L

P-1.0

- Chamber Volume: 1 L (1,000 mL)

- Power: 5 HP

- Min Batch Volume: 2 L

P-1.5

- Chamber Volume: 1.5 L (1,500 mL)

- Power: 7.5 HP

- Min Batch Volume: 2.5 L

P-2.0

- Chamber Volume: 2 L (2,000 mL)

- Power: 7.5 HP

- Min Batch Volume: 3 L

Pilot Mill Features

Self-Contained or External Pump

The Pilot Mill comes with a built-in variable flow rate feed pump, ideal for precise control of low to high viscosity products. For larger volumes or specialized applications, an external pump option is available.

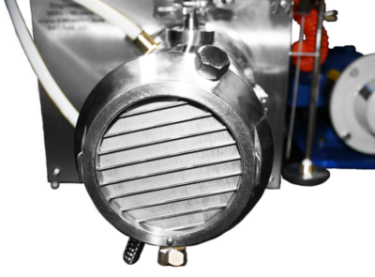

Bead Separation Options

The Pilot Mill offers a range of bead sizes, including options for ceramic, glass, steel, and more. Bead separation options can be customized to ensure proper size distribution and efficient milling for various particle sizes, even down to sub-micron levels.

Temperature Control

The Pilot Mill is designed for efficient temperature regulation, with options for water-jacketed chambers. This ensures stable processing conditions and prevents overheating during extended milling sessions. Chillers are available if needed.

Simple Cleaning

Quick-release chamber closures and piping simplify cleaning between runs, minimizing downtime. A suitable solvent can be added during the re-circulation process for easy cleaning of the system.

Custom Controls

The Pilot Mill offers optional PLC controls, including color display and advanced programming for monitoring process variables. This includes data collection and automatic adjustments, providing full control for optimized performance.

Lab Milling and Pilot Mill FAQs

What is lab milling?

Lab milling refers to the process of reducing the particle size of materials in a controlled, small-scale setting. Media milling uses grinding media to achieve this. It is essential for R&D, quality control, determining the best milling conditions, and ensuring that results can be scaled effectively for production.

What is a lab mill?

A lab mill is a small-scale milling device used to reduce the particle size of materials. Media mills use grinding media to accomplish this. Commonly used for small batches, R&D, and gathering data before scaling up to full production.

Why is pre-mixing important for efficient milling?

Pre-mixing breaks down large particles and evenly distributes materials, which improves overall milling efficiency. This ensures more uniform dispersion, reduces wear on the mill, and shortens processing times, leading to consistent product quality. Our lab mixers are a great place to start.

What is the difference between single-pass and recirculation milling?

Single-pass milling involves feeding material through the mill once, while recirculation milling sends the material through multiple times. Recirculation can help achieve finer particle sizes and more uniform dispersion by allowing the material to interact with the grinding media more thoroughly.

What types of materials can be processed in the Pilot Mill?

The Pilot Mill is designed for a wide range of liquid and paste viscosities, including coatings, inks, cosmetics, pharmaceuticals, specialty chemicals, and more.

How does the Pilot Mill scale to production?

Data obtained from the Pilot Mill predicts production outcomes, ensuring a seamless transition from small batches to full-scale manufacturing. When you are ready to scale, find the Production Mill.

What grinding media can be used in the Pilot Mill?

The Pilot Mill accommodates various grinding media, including ceramic, glass, steel, and others, allowing customization based on your specific application. For new or replacement grinding media, visit our grinding media page.

Can the Pilot Mill be customized?

Yes! Chamber sizes, materials of construction, control systems, feed pump options, and more can be tailored to meet your specific requirements.

Lab Milling and Pilot Mill FAQs

What is lab milling?

Lab milling refers to the process of reducing the particle size of materials in a controlled, small-scale setting. Media milling uses grinding media to achieve this. It is essential for R&D, quality control, determining the best milling conditions, and ensuring that results can be scaled effectively for production.

What is a lab mill?

A lab mill is a small-scale milling device used to reduce the particle size of materials. Media mills use grinding media to accomplish this. Commonly used for small batches, R&D, and gathering data before scaling up to full production.

Why is pre-mixing important for efficient milling?

Pre-mixing breaks down large particles and evenly distributes materials, which improves overall milling efficiency. This ensures more uniform dispersion, reduces wear on the mill, and shortens processing times, leading to consistent product quality. Our lab mixers are a great place to start.

What is the difference between single-pass and recirculation milling?

Single-pass milling involves feeding material through the mill once, while recirculation milling sends the material through multiple times. Recirculation can help achieve finer particle sizes and more uniform dispersion by allowing the material to interact with the grinding media more thoroughly.

What types of materials can be processed in the Pilot Mill?

The Pilot Mill is designed for a wide range of liquid and paste viscosities, including coatings, inks, cosmetics, pharmaceuticals, specialty chemicals, and more.

How does the Pilot Mill scale to production?

Data obtained from the Pilot Mill predicts production outcomes, ensuring a seamless transition from small batches to full-scale manufacturing. When you are ready to scale, find the Production Mill.

What grinding media can be used in the Pilot Mill?

The Pilot Mill accommodates various grinding media, including ceramic, glass, steel, and others, allowing customization based on your specific application. For new or replacement grinding media, visit our grinding media page.

Can the Pilot Mill be customized?

Yes! Chamber sizes, materials of construction, control systems, feed pump options, and more can be tailored to meet your specific requirements.