The PRODUCTION MILL

Horizontal Media Mill

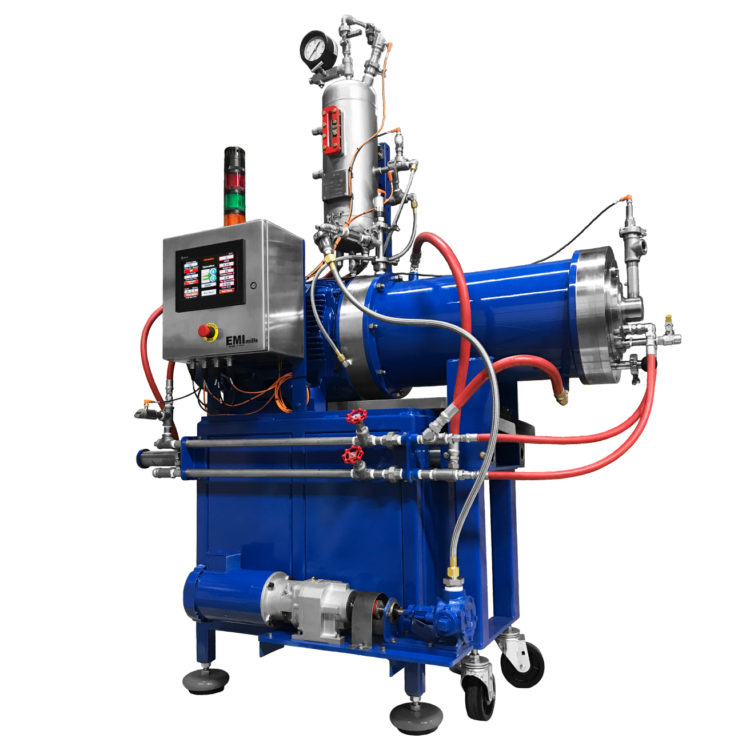

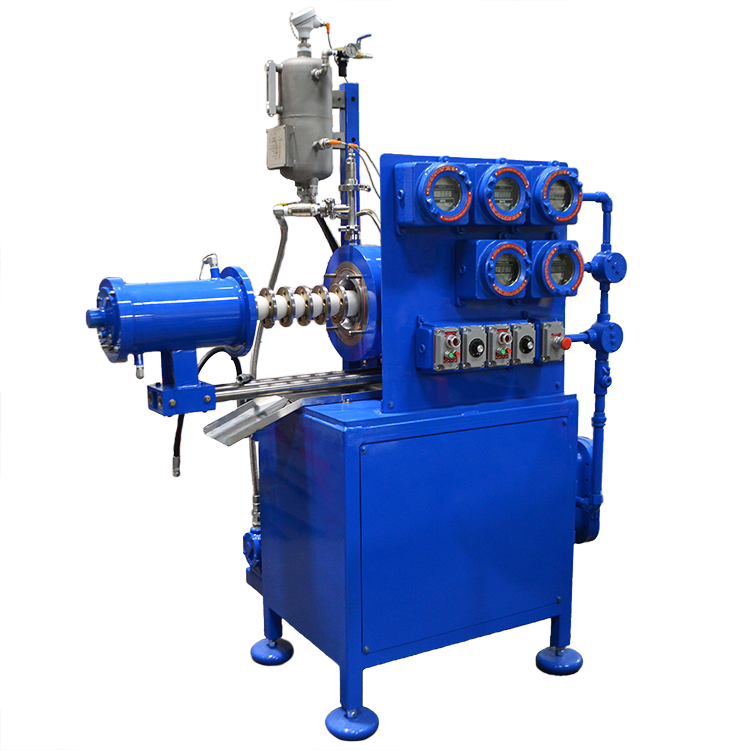

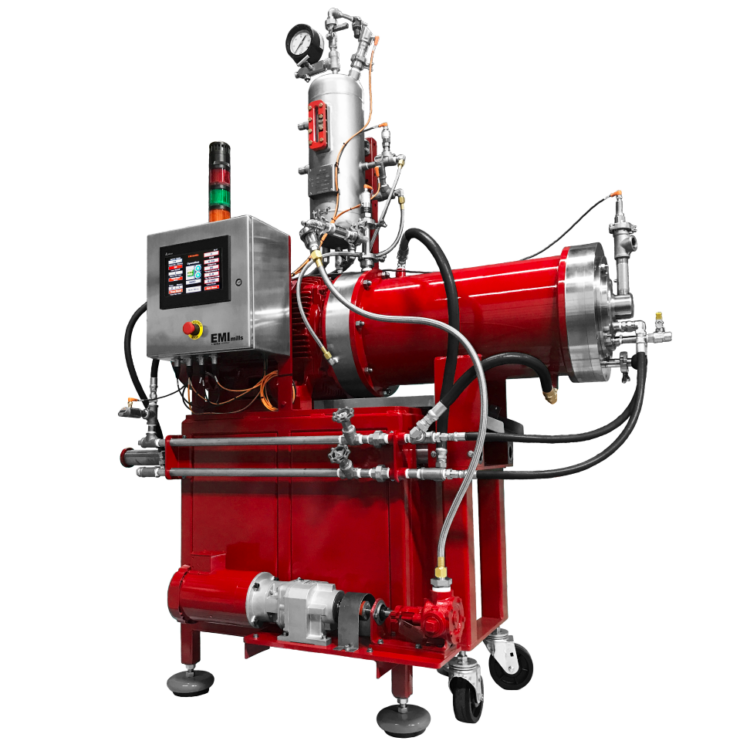

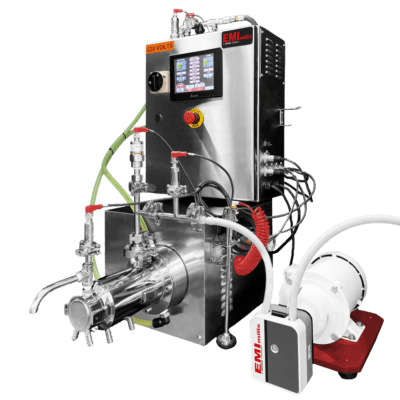

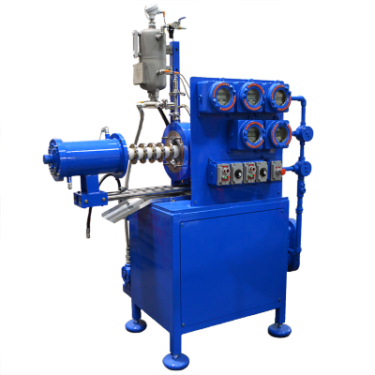

The Production Mill is a horizontal media mill designed for large-scale wet milling, fine grinding, and particle dispersion. Commonly used for producing paints, inks, coatings, specialty chemicals, cosmetics, pharmaceuticals, and more. The direct drive system maximizes energy transfer, while the water-jacketed chamber and end plates regulate temperature. With variable agitator speeds and advanced media separation, the Production Mill delivers control over particle size and dispersion quality.

Standard Batch Size: 30 – 5,000 gallons (~110 L – 20 kL)

- Narrow particle size distribution for stable dispersions

- Single pass or recirculation milling for process flexibility

- Variable agitator tip speeds for precise energy input

- Water-jacketed chamber and end plates for temperature control

- PLC/HMI controls for monitoring, diagnostics, and data collection

- Explosion-proof motor and control options available

- Customizable to meet specific processing needs

Want a lab-scale option? The Mini Mill and Pilot Mill are perfect for product research, testing, and quality control before scaling up to production. Pre-mix equipment? SCHOLD industrial mixers ensure effective pre-mixing and dispersion, providing a seamless transition from raw materials to final product.

Description

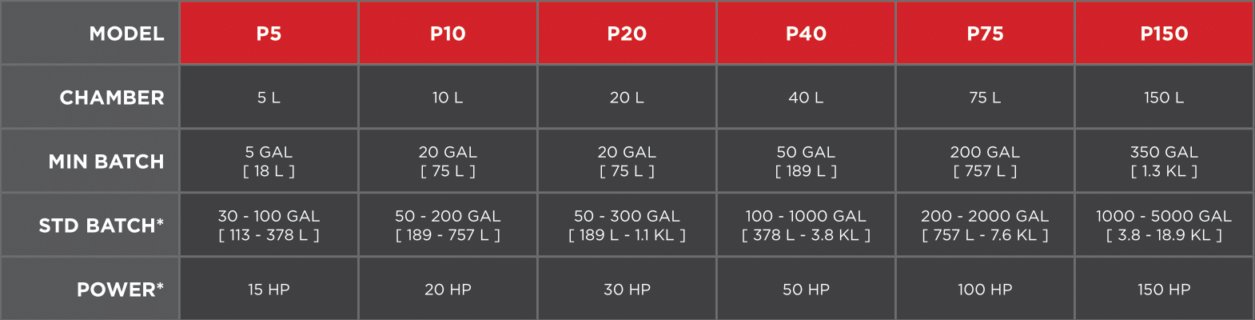

Production Mill Specifications

Note: Each model can produce smaller or larger volumes. The chart below is a starting reference. Agitator tip speeds range from 0-16 m/s for all models. Consult with our team about your application(s).

P5

- Chamber Volume: 5 L

- Min Batch: 5 gallons (18 L)

- Standard Batch: 30–100 gallons (113–378 L)

- Power: 15 HP

P10

- Chamber Volume: 10 L

- Min Batch: 20 gallons (75 L)

- Standard Batch: 50–200 gallons (189–757 L)

- Power: 20 HP

P20

- Chamber Volume: 20 L

- Min Batch: 20 gallons (75 L)

- Standard Batch: 50–300 gallons (189 L–1.1 KL)

- Power: 30 HP

P40

- Chamber Volume: 40 L

- Min Batch: 50 gallons (189 L)

- Standard Batch: 100–1,000 gallons (378–3.8 KL)

- Power: 50 HP

P75

- Chamber Volume: 75 L

- Min Batch: 200 gallons (757 L)

- Standard Batch: 200–2,000 gallons (757 L–7.6 KL)

- Power: 100 HP

P150

- Chamber Volume: 150 L

- Min Batch: 350 gallons (1.3 KL)

- Standard Batch: 1,000–5,000 gallons (3.8–18.9 KL)

- Power: 150 HP

Production Mill Features

Single Pass or Recirculation

Choose between single-pass milling for high-throughput production or recirculation mode for controlled, repeatable processing to achieve the desired particle size and dispersion.

Direct Drive System

Energy-efficient design eliminates unnecessary components, delivering 100% power to milling for maximum throughput and simplified maintenance.

Integrated Feed Pump

Configurable to meet process requirements, the included feed pump controls product flow, optimizing milling for both small and large batches.

Variable Agitator Speeds

Adjustable agitator tip speeds up to 16 m/s provide precise control over shear and impact forces, optimizing milling performance across different materials and viscosities.

Advanced Media Separation

The high-flow screen media separation system efficiently handles various grinding media sizes, preventing clogging and ensuring smooth operation across different applications.

Temperature Control

The water-jacketed milling chamber and optional end plate cooling help maintain consistent processing temperatures, preventing overheating and ensuring product stability. Chillers are available if needed.

Customizable PLC/HMI Controls

User-friendly touchscreen controls provide real-time monitoring, process automation, data recording, and diagnostics for greater milling efficiency. Explosion-proof (XP) controls are available for hazardous environments (pictured).

Industrial Milling and Production Mill FAQs

What is industrial milling?

Industrial milling refers to the process of breaking down, dispersing, or grinding solid particles in a liquid medium. It is commonly used in coatings, inks, pharmaceuticals, and specialty chemicals to achieve uniform particle size distribution and stable dispersions.

Why is particle size reduction important?

Smaller, more uniform particles improve product performance, stability, and appearance. Narrow particle size distribution enhances product characteristics (color strength for example), viscosity control, and overall formulation consistency.

What is the difference between single-pass and recirculation milling?

Single-pass milling processes material through the mill once, providing a streamlined approach for specific applications. Recirculation milling allows material to pass through multiple times, enabling finer grinding and better dispersion control. Our milling experts can guide you to the optimal choice for your application.

How does temperature affect the milling process?

Temperature impacts viscosity, particle breakdown, and overall milling efficiency. The Production Mill includes a water-jacketed chamber and end plates to regulate temperature and maintain optimal processing conditions. If needed, we supply chillers for both lab and production processes.

What type of grinding media is best for my application?

The right media depends on your material properties and milling goals. Grinding media options include ceramic, steel, glass, and other beads in various sizes. Our team can help select the best grinding media for your process.

What batch sizes can the Production Mill handle?

The Production Mill is available in multiple chamber sizes, accommodating batch sizes from 30 to 5,000 gallons (~110 L – 20 kL), depending on the model and process requirements.

What types of applications are best suited for the Production Mill?

The Production Mill is ideal for high-volume, continuous wet milling applications that require consistent particle size reduction and dispersion. Common industries and applications include:

-

Paints & Coatings

Achieving smooth, uniform finishes with controlled particle size distribution.

-

Inks

Producing high-quality printing inks with excellent color strength and stability.

-

Agrochemicals

Milling pesticides, herbicides, and fertilizers for enhanced performance.

-

Pharmaceuticals

Ensuring uniformity and fine particle dispersion in active ingredients.

-

Battery & Energy Storage

Processing materials like graphite and lithium for battery production.

-

Ceramics & Advanced Materials

Producing fine powders and high-performance materials.

-

Cosmetics & Personal Care

Creating smooth, consistent formulations for makeup, skincare, and other beauty products.

How does the Production Mill ensure uniform product quality?

The Production Mill features variable agitator speeds, controlled pump flow rates, and process monitoring via PLC/HMI controls to maintain consistency across batches.

Can the Production Mill be customized?

Yes, customization options include chamber sizes, milling discs, grinding media separation, control systems, explosion-proof components, and complete milling system integration.

What are the benefits of the direct drive system?

The direct drive agitator maximizes energy efficiency by delivering 100% of available horsepower to the milling process, reducing mechanical losses.

How easy is it to clean and maintain the Production Mill?

The Production Mill’s slide rail system simplifies maintenance, product changeovers, and media replacement, while quick-connect piping allows for easy cleaning between batches. Contact us if you need assistance.

Industrial Milling and Production Mill FAQs

What is industrial milling?

Industrial milling refers to the process of breaking down, dispersing, or grinding solid particles in a liquid medium. It is commonly used in coatings, inks, pharmaceuticals, and specialty chemicals to achieve uniform particle size distribution and stable dispersions.

Why is particle size reduction important?

Smaller, more uniform particles improve product performance, stability, and appearance. Narrow particle size distribution enhances product characteristics (color strength for example), viscosity control, and overall formulation consistency.

What is the difference between single-pass and recirculation milling?

Single-pass milling processes material through the mill once, providing a streamlined approach for specific applications. Recirculation milling allows material to pass through multiple times, enabling finer grinding and better dispersion control. Our milling experts can guide you to the optimal choice for your application.

How does temperature affect the milling process?

Temperature impacts viscosity, particle breakdown, and overall milling efficiency. The Production Mill includes a water-jacketed chamber and end plates to regulate temperature and maintain optimal processing conditions. If needed, we supply chillers for lab and production processes.

What type of grinding media is best for my application?

The right media depends on your material properties and milling goals. Grinding media options include ceramic, steel, glass, and other beads in various sizes. Our team can help select the best grinding media for your process.

What batch sizes can the Production Mill handle?

The Production Mill is available in multiple chamber sizes, accommodating batch sizes from 30 to 5,000 gallons (~110 L – 20 kL), depending on the model and process requirements.

What types of applications are best suited for the Production Mill?

The Production Mill is ideal for high-volume, continuous wet milling applications that require consistent particle size reduction and dispersion. Common industries and applications include:

-

Paints & Coatings

Achieving smooth, uniform finishes with controlled particle size distribution.

-

Inks

Producing high-quality printing inks with excellent color strength and stability.

-

Agrochemicals

Milling pesticides, herbicides, and fertilizers for enhanced performance.

-

Pharmaceuticals

Ensuring uniformity and fine particle dispersion in active ingredients.

-

Battery & Energy Storage

Processing materials like graphite and lithium for battery production.

-

Ceramics & Advanced Materials

Producing fine powders and high-performance materials.

-

Cosmetics & Personal Care

Creating smooth, consistent formulations for makeup, skincare, and other beauty products.

How does the Production Mill ensure uniform product quality?

The Production Mill features variable agitator speeds, controlled pump flow rates, and process monitoring via PLC/HMI controls to maintain consistency across batches.

Can the Production Mill be customized?

Yes, customization options include chamber sizes, milling discs, grinding media separation, control systems, explosion-proof components, and complete milling system integration.

What are the benefits of the direct drive system?

The direct drive agitator maximizes energy efficiency by delivering 100% of available horsepower to the milling process, reducing mechanical losses.

How easy is it to clean and maintain the Production Mill?

The Production Mill’s slide rail system simplifies maintenance, product changeovers, and media replacement, while quick-connect piping allows for easy cleaning between batches. Contact us if you need assistance.